RD-Biotech’s antibody engineering platform offers a complete range of custom services.By contacting RD-Biotech, you will:

Monoclonal antibody production

Monoclonal antibodies against murine, rat, guinea pig, or other species. Capacities of up to several tens of grams.

RD-Biotech has developed expert know-how in the development and in vitro production of monoclonal antibodies.

Ascites production, which is still authorized in France, is acknowledged as being very painful for animals and can now be advantageously replaced by cell culture. With its in vitro production unit, RD-Biotech offers not only alternative technologies at an equivalent cost to ascites production, but also better reproducibility and higher purity quality compared to ascites production.

When the customer entrusts his clone to RD-Biotech (in flasks or cryotubes) for in vitro production, it is not necessary to specify the clone’s specificity, thus providing a guarantee towards customer confidentiality.

With more than 500 clones produced each year, RD-Biotech has developed unparalleled expertise in the production of monoclonal antibodies, for research applications or preclinical studies.

Whether you want 1 mg of purified antibody for an R&D study or 500 mg “endofree” for in vivo applications, our goal is to meet your demands, in terms of quantity, quality and deadline.

Several quality grades, adapted to your applications:

“Endofree” Research & Development grade

For your R&D and preclinical applications.

- Large production capacity: from a few milligrams up to several grams. QUANTITY GUARANTEED!

- Hybridoma of mice, rats, guinea pigs, or other species

- Very short deadlines

- Homogeneity of the batches produced

- Possibility of secure storage for recurring productions

- Adaptation of the process in the event of low / bad producing clones

- Standard quality controls included, without additional cost: Determination of total proteins by spectrophotometer measurement (Ig standard) and analysis of total proteins by SDS-PAGE electrophoresis.

- “Endofree” quality (for in vivo applications): We guarantee an endotoxin level of less than 1 EU / mg of Ig (use of pyrogen-free buffers, harvest in sterile conditions, sanitization of equipment, pyrogen-free purification conditions, LAL test)

- Adaptation to a specific and appropriate culture medium

- Concentration of the supernatant

- Adjustment of antibody concentration

- Filtration

- Aliquoting

- A full range of quality controls available on demand

- Controls of specificity, of biological activity…

- Modification of antibodies: fragmentation, coupling,

- VH/VL Sequencing to secure the antibody or to switch to a recombinant mAb production

- Integration into an in vitro diagnostic kit

- Research use

- Candidates in a therapeutic program framework

- Vaccine controls

- Biologically active antibodies

- Reference standards

High Quality Grade (GMP “like” grade)

Production of superior quality monoclonal antibodies, suitable for preclinical applications.

- Full traceability and documentation regarding reagents and operators

- Large-scale culture performed without antibiotics

- The production process is carried out “animal free” – without substances of animal origin

- Storage of the cell bank in a secured area

- Additional controls available to ensure high purity of the product

- Quality controls adapted to the specifications of your project (list of QCs upon request)

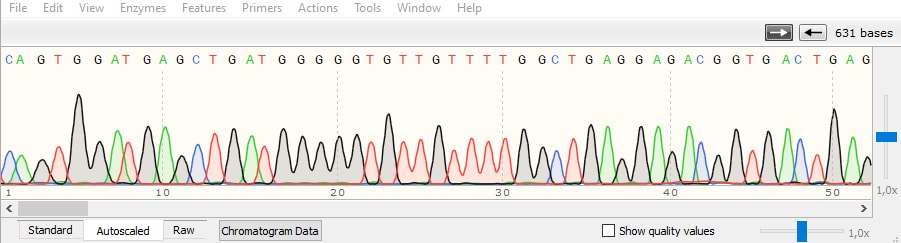

Monoclonal antibody in vitro production

The different stages of an in vitro antibody production program are as follows:

The customer provides the hybridoma (frozen cells or cells in culture) accompanied by a technical sheet in which the culture medium, the nature and the isotype of the antibody will be specified. The hybridoma can be adapted to different culture media (serum-free medium, depleted serum in bovine IgG, etc.). The antibody can be produced and purified in Endotoxin free conditions.

For the production of large quantities of monoclonal antibodies (over 100 mg) RD-Biotech can carry out a productivity assessment on small volumes (pilot step). At the end of this feasibility phase, the customer receives a report indicating the productivity and an adaptated quotation for the production phase. The customer may also receive the antibody for evaluation before ordering the in vitro production phase.

RD-Biotech’s scale up ranges from 1 liter to more than 300 liters of culture supernatant, which yields between a few mg and several tens of grams of antibody.

Different production technologies are available, allowing the cultivation conditions to be adapted to the clone (depending on its productivity, the desired quantity, etc.). Production in Rollers, T-Flasks, possibility to produce in FiberCell, Spinner flasks or CELLine tm.

Thanks to the assay kits for mouse IgG, rat IgG and human IgG developed and marketed by RD-Biotech (FastELISA range) , we can monitor the antibody production in the culture supernatant in order to estimate very quickly the amount of supernatant to produce the targeted quantity.

The supernatant produced can then be concentrated up to 15 times by tangential ultrafiltration.

The supernatant can then either be delivered to the customer or RD-Biotech can carry out the purification of the monoclonal antibody.

Antibody purification

Purification of monoclonal antibodies (Immunoglobulins IgG, IgM, IgA, IgY…):

Purification from serum, plasma, culture supernatant or egg yolk.

Using the FastELISA technique for the quantification of mouse IgG, rat IgG or human IgG, RD-Biotech can rapidly monitor the level of immunoglobulin G in the sample and estimate the amount that it will be possible to purify.

- Purification of monoclonal antibodies by affinity chromatography on Protein A, Protein G, or other affinity resin, depending on the origin and isotype of the clone (IgG, IgA, etc.)

- Purification by ion exchange chromatography, in particular for the purification of IgM

- Purification by specific affinity: allowing isolation from a specific ligand (peptide, antigen, etc.)

- Purification by precipitation, for example with ammonium sulphate

- Purification by gel filtration

After the affinity chromatography step, the purity of the antibody can be improved by different methods:

- By size exclusion chromatography (preparative SEC), a step which will remove the aggregates;

- With an ion exchange chromatography step, which also removes any endotoxins that may be present.

Antibody produced in vitro can be purified in “Endofree” conditions, this requires the use of non-pyrogenic buffers and containers. The monoclonal antibodies produced in vitro by RD-Biotech in “Endofree” conditions have an endotoxin level of less than 1 EU / mg.

Quality controls

The standard package includes the following controls which guarantee the quality of the antibodies produced and / or purified

- Analysis of total proteins by SDS-PAGE electrophoresis

- Determination of total proteins by absorbance measurement with a spectrophotometer (Ig standard adapted to the isotype)

Monoclonal antibodies produced in vitro can be delivered to the customer after concentration and in the desired buffer, along with a complete purification report.

- Mycoplasma test

- LAL test to determine the level of bacterial endotoxins. The LAL (Limulus Amebocyte Lysate) test is performed using a regulatory kit according to the supplier’s protocol

- Bacterial and fungal contamination test

- Control by analytical SEC

- Desalting of antibodies

- Control of specificity, biological activity … (ELISA, Western Blotting, Octet, Cytometry, custom bioassays …)

- Determination of Protein A residues (RD-Biotech FastELISA)

- Determination of bovine immunoglobulin contaminants (RD-Biotech FastELISA)

Specific controls will be applied in the case of a “High Quality Grade” purification process.

Cell banks

Master cell bank and working cell banks

Custom backup banks of your hybridoma:

- from cells supplied in culture or frozen

- during the cell amplification step before production

- or at the end of the clone development process.

- Cell amplification

- If necessary, perform a productivity test with the FastELISA Kit.

- Freezing of cells in exponential growth step with 100% viability: 10 vials of 5 million cells

- Bank controls (cell viability and absence of contamination by mycoplasmas)

- Freezing of the cryotubes at -80 ° C and in liquid nitrogen before shipment to the customer, accompanied by quality control certification.

- Storage in liquid nitrogen (controlled zone)

- Bank stability controls during the storage (productivity and specificity)

Antibody coupling

Coupling, Fragmentation and other modifications:

RD-Biotech carries out the fragmentation of the monoclonal antibody or the polyclonal antibody (pepsin, papain, etc.) and / or the coupling of the antibodies with different markers:

- Peroxidase labelling (HRP)

- Alkaline phosphatase (PAL) labelling

- Biotin labelling

- Labelled with a fluorescent marker (Fluorescein FITC, Cyanine, Alexa fluor,…)

The antibody couplings are executed according to robust protocols, carried out routinely by our teams.

After modification of the antibody and quality control, the sample is shipped to the customer with a full report.

LUMINEX platform

Partnership agreement with Luminex Corporation

RD-Biotech now offers a range of custom services with Luminex xMAP® technology!

- Antigen or antibody coupling with Luminex beads

- Analytical service: detection and quantification of analytes, mono or multiplex analysis using the Luminex 200 equipments

- Development of multiplexed assay

From providing labeled analytes to assay development, RD-Biotech can help you get to your Multiplexed assay—faster.

Advantages of Luminex technology

- Multiplex analysis of up to 100 analytes

- High sensitivity

- Low sample volume

- Limited matrix interference

- Rapid analysis

Development of monoclonal antibodies

RD-Biotech offers support for your monoclonal antibody projects in mice, with the supply of validated clone cell banks.

Our technical and scientific expertise, combined with that of the mAbexpert group, allow us to offer:

- The support for the expression of antigens (sequence analysis, preparation of peptides or recombinant proteins

Discover recombinant proteins - An extended screening platform: ELISA, Western Blotting, Cytometry, Octet…

Discover analytical services - The characterization of the monoclonal antibodies developed: specificity, affinity, bioactivity

Discover analytical services - The expertise and technological tools to secure your clone or to switch to recombinant antibodies (antibody sequencing, chimerization, humanization, etc.)

Discover recombinant antibodies - The generation of hybridomas in other species (rat, guinea pig)

- Phage Display technologies (mouse, rat, other species)

The different stages of an immunization program and hybridoma generation are described below, based on a Go No Go procedure.Before starting a new project, RD-Biotech advises to perform a preparatory meeting that will validate the different stages of the process: antigens, immunization routes, choice of host, mode of screening, differential screening, etc.

Preparation of the immunogen

Starting material provided by the customer:

- The immunogen or group of immunogens: protein of interest, native or recombinant, peptide, peptide sequence in a computer file, …

- The molecules necessary for the screening steps (antibodies, protein peptides, cell lysate, etc.)

RD-Biotech can also take on charge the preparation of immunogen(s)

- Feasibility study: antigen design, sequence analysis, optimization,…

- Production of the immunogen, coupling to a carrier, …

Hybridoma Generation

- Immunization of 4 mice (standard package that can be adapted according to the project)

- Immunization of mice : footpad injection (intrapodal) (28 days), or intraperitoneal injection (49 days)

- Number of injections and boosts adapted to the immunization protocol.

- The immune response is followed by ELISA titration or Western-blotting.

- The results are sent to the client.

- Go No Go: validation of the titration results by the customer

- The fusion is carried out after selection of the mice in agreement with the client.

- Maintenance of hybridomas on selective medium

- Screening of all hybridoma supernatants by ELISA

- Other methods can be proposed: Dot-Blot, Western blotting, flow cytometry, Octet or other methods.

Discover analytical services - After primary screening, the positive hybridomas are subcultured for secondary control

- Isotyping and saving of significantly positive hybridomas

- Possibility of sending positive supernatants to the client for additional tests and for the selection of the best performing hybridomas

- Go No GO: choice of candidates for cloning

- Cloning by two rounds of limiting dilution

- Screening of the supernatants after each series of cloning (ELISA or other methods of your choice)

We pay special attention in the early stages of cloning to avoid the loss of hybrids which may be of interest but unstable before the monoclonal stage.

- Isotyping of clones (FastELISA rdb-3255 Kit)

- If necessary, preparation of mini-productions and shipments to the customer for additional controls

- Constitution of master banks for each selected clone with the freezing of 10 vials of 5 million cells

- Additional vials are prepared for bank controls (freeze/thaw viability and absence of mycoplasma contamination)

- Safe storage of banks (to be specified)

Monoclonal antibody sequencing

Back up clones:

Sequencing can be offered from the early stages of the process, to secure the clones.

Development of recombinant Antibodies:

Sequencing may allow the development of recombinant antibodies.

Candidate characterization

RD-Biotech offers different methods for the characterization of candidates: specificity, biological activity…

- ELISA

- Western Blotting

- Flow cytometry

- Octet

- Bioassay platform (ADCC, CDC, etc.)

Clone rescue

Different strategies can be implemented, including the recloning of the clones of interest.

Development and production of polyclonal antibodies

RD-Biotech develops custom polyclonal antibodies from different types of immunogens (purified protein, peptide, cell lysate, etc.).

The most widely used species is the rabbit, but we also have the possibility of developing chicken antibodies (IgY).

Other services

Our sales team as well as our scientific and technical experts are at your disposal to offer you the service adapted to your request.